Lintec has access to hundreds of label constructions to fit your brand.

Our products range from papers or films, clear, white or coloured, rubber or acrylic, removable or permanent, paper or PET, roll-to-roll or layflat. We will work with you to combine the right substrate, adhesive and liner to fit your needs.

Whether for Food, Beverage, Health Care, Automotive, or Shipping, we have the right label for you.

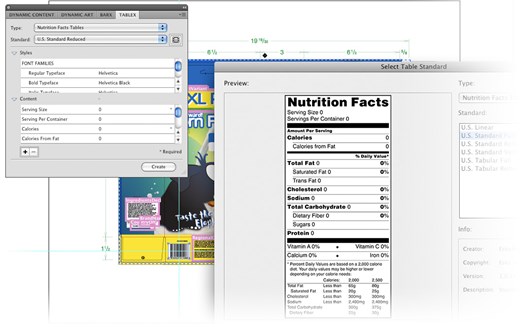

Lintec produces all of our high definition plates in-house. Using Esko software with Dupont Cyrel Digital Imager (CDI) allows Lintec to manage artwork every step of the way, from proof to press, with no third party involvement. Our water wash plate process is solvent free, reducing our environmental footprint.

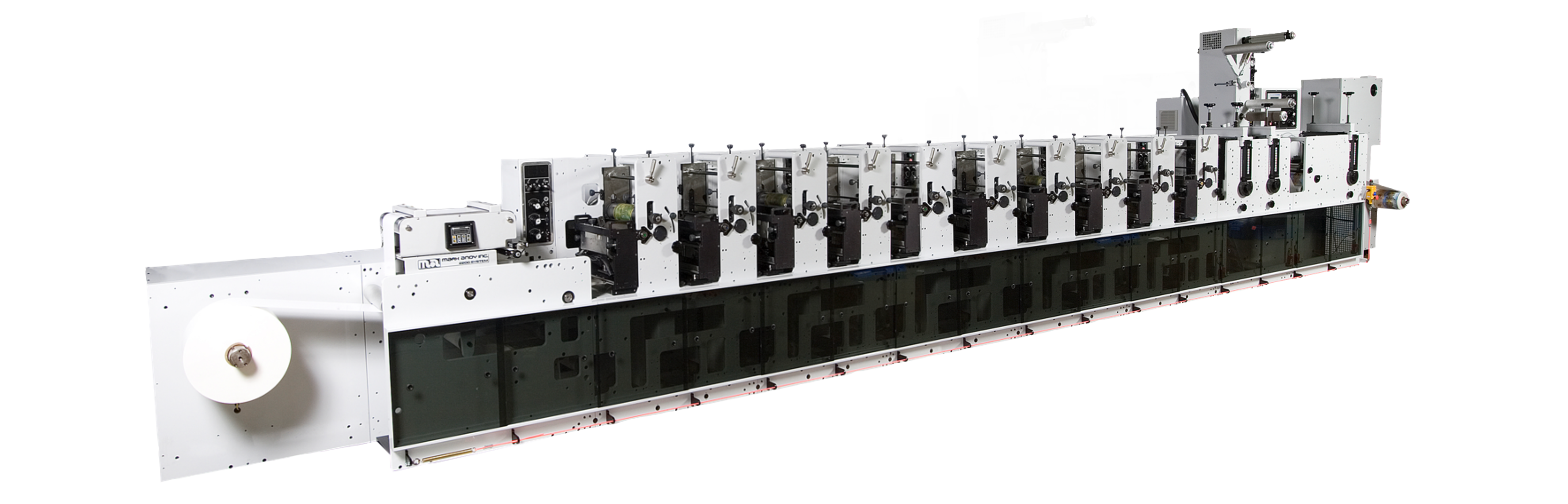

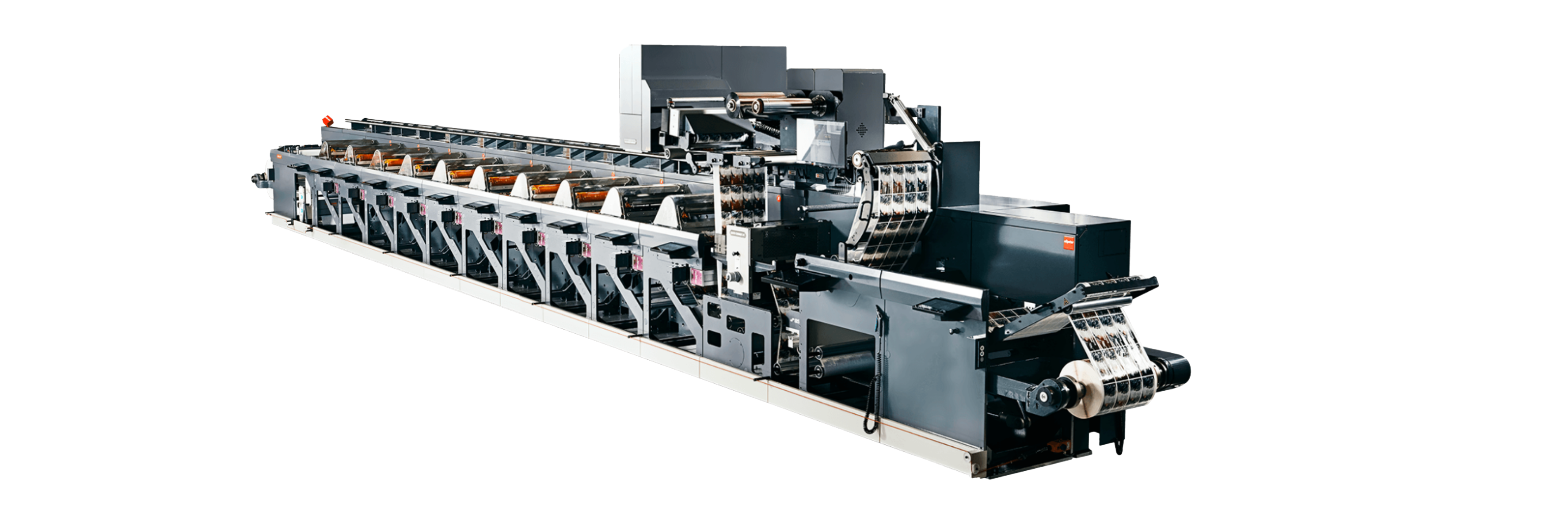

Our Mark Andy flexographic presses are all kept maintained in top condition. The operators on our team bring between 10 and 30 years of experience in flexography to our press room. We are capable of printing from 0 to 10 colours at a time, including options for printing on the liner and adhesive and a variety of coatings or laminations. We die cut all shapes and sizes to your specification and can add perforations, undercuts and sheeting all in-line on our versatile equipment. Our Mark Andy Digital press brings another dimension to Lintec - using a CMYK print engine instead of plates and ink, as well as the capability to print plated whites, digital can be an ideal solution for short runs, varied SKUs or one-time only promotions. Each of our presses, including digital, uses the same tooling and materials, giving us the flexibility and reliability to produce your labels.

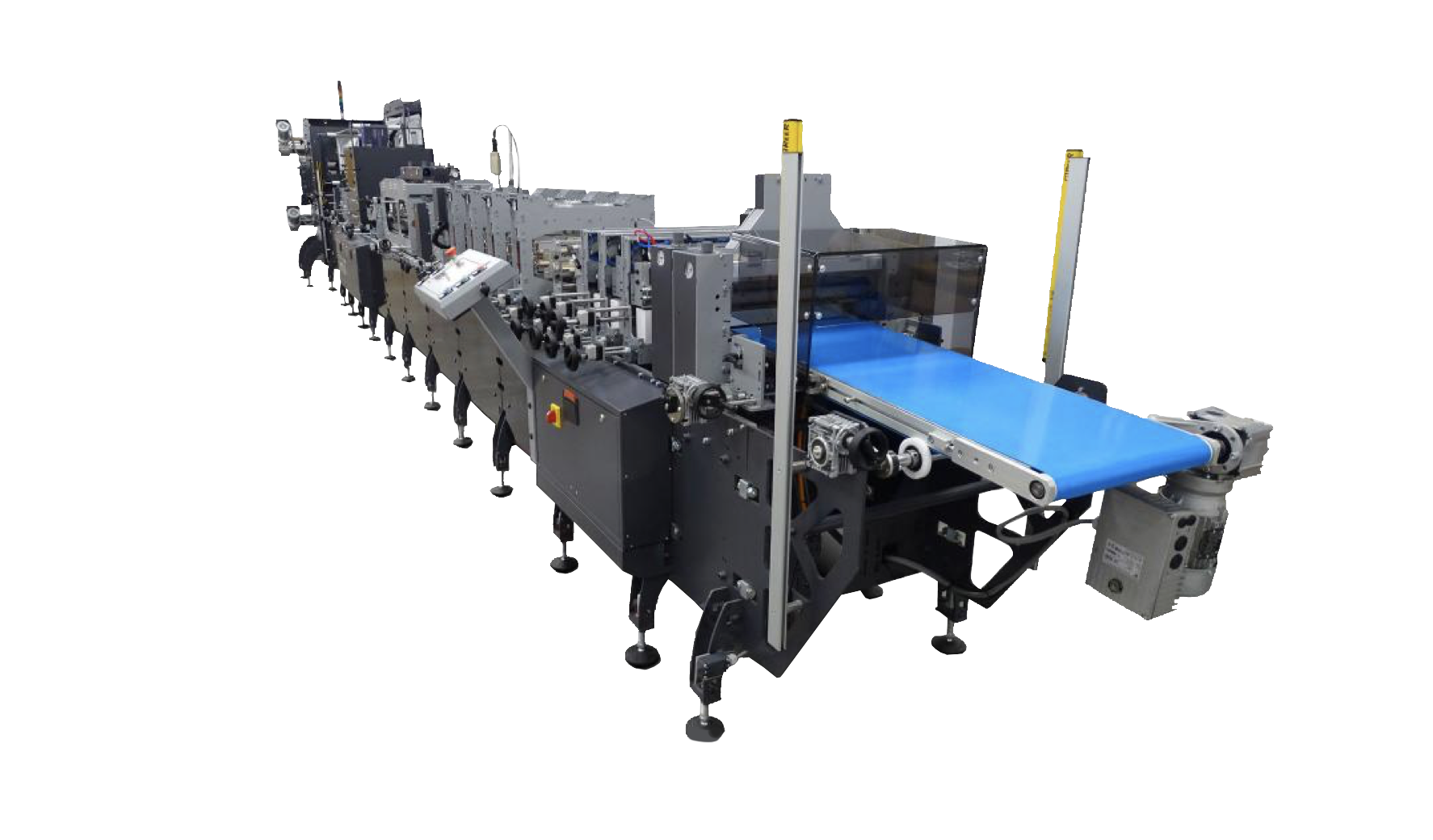

Our rewind department is well equipped to meet your finished roll requirements. Capable of up to 15" outside diameter and inside core diameters ranging from 0.75" to 3". Each of our slitter-rewinders employs measures to ensure quality control prior to packaging. This includes two vision systems, which automatically compares each label to a set target. We can also offer back-numbering to support your quality systems.